Acrylic production technology and process is introduced

by:Noble Awards

2020-07-05

With yakeli the application of this material in various industries, also take the form of a variety of acrylic products in our field of vision, affect our life, relative acrylic craft is also more and more mature, is to introduce the processing technology of acrylic today.

Process and process: 1, cutting, laser cutting is a kind of contactless cutting method, the laser can cut all sorts of design, wording, such as, laser cutting technology is the use of laser beam to the acrylic surface, then release energy to make acrylic laser melting.

Use laser cutting cutting processing can be all kinds of complicated images, words, or logo, etc, so that it can work out in accordance with our processing requirement of complex shapes, after cutting the materials as long as after polishing treatment can restore acrylic material itself has a high transparency.

2, punch: acrylic can be used directly drilling holes, compared with glass, acrylic has a very good machining features.

According to the requirements of machining drawing directly on the drilling machine with fixed well, ps directly.

Acrylic can also use the CNC punch, this process of acrylic fittings have very high assembly accuracy, we only need to input on the computer drawing on various parameters, and can locate processing using a computer controlled CNC machine punch.

3, polishing: acrylic itself has high transparency, comparable to the natural production of crystal, so we need to recover after polishing processing, such as crystal acrylic itself has high transparency, and acrylic polishing can use the traditional cloth round of polishing can also use the diamond polishing, fire polishing.

After order is generally diamond polishing;

In the fire polishing is used to eliminate the bottom of the burr, make acrylic products smooth;

Finally the cloth wheel polishing, after a wax on the cloth wheel can be polished out of more than 92% acrylic products out of transparency.

4, hot bending: because acrylic materials in 70 & deg;

To 100 & deg;

When it comes to soften, so the use of hot bending technology can make acrylic processing into various shapes and we need to irregular parts.

The hot bending of acrylic can use different ways to achieve, can at the same time will be a lot of pieces of acrylic on a set of hot bending machine and finalize the design on the mold hot bending finalize the design, the vast majority of hot bending only by single or parallel hot bending, hot bending Angle can be set mode to control the Angle according to need.

5, adhesive, adhesive is a very important process, all by manual processing, so this time the employee's experience is very important, and the bonding process of acrylic products to strict control, not only to the position of drawing design for adhesive, also can't stick slanting, foaming, glue rickety, that will make strict control of product after shipment is allowed.

6, the assembly: the final assembly is self-evident, will be processed all kinds of acrylic fittings together, and then completed a complete product.

This time also have to be the final quality inspection of the entire product, make sure you have supplied before shipment to the product packaging.

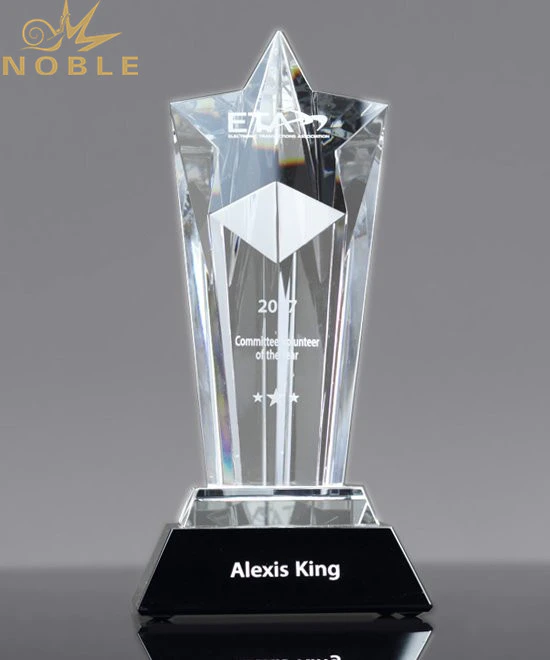

Noble Awards Co.,ltd. is famous for creating innovative products like the custom trophies and supporting their market leadership with savvy marketing campaigns to build an elite brand.

Noble Awards Co.,ltd. will make a healthy profit for its owners and provide a rewarding work environment for its employees.

Consumers like these are interested not just in custom trophies they will spend their money on, but also in the human and environmental impact of the supply chain that produces those goods.

Noble Awards Co.,ltd. has been making a name for itself as a producer of some of the finest in the China, and it has been singing its praises for some time.

We afford not only the best product but also the comprehensive service, satisfy the customer's demands.

Noble Awards Co.,ltd. is famous for creating innovative products like the custom trophies and supporting their market leadership with savvy marketing campaigns to build an elite brand.

Noble Awards Co.,ltd. will make a healthy profit for its owners and provide a rewarding work environment for its employees.

Consumers like these are interested not just in custom trophies they will spend their money on, but also in the human and environmental impact of the supply chain that produces those goods.

Noble Awards Co.,ltd. has been making a name for itself as a producer of some of the finest in the China, and it has been singing its praises for some time.

We afford not only the best product but also the comprehensive service, satisfy the customer's demands.

Custom message